Real-time inspection and control system for nanoµ-perforation

Vision Master

SEI Laser, leader in laser technology, introduces a strategic innovation for the flexible packaging market: Vision Master, a high-performance integrated vision and control system, capable of conducting real-time and individual inspection of each micro-hole produced by the laser.

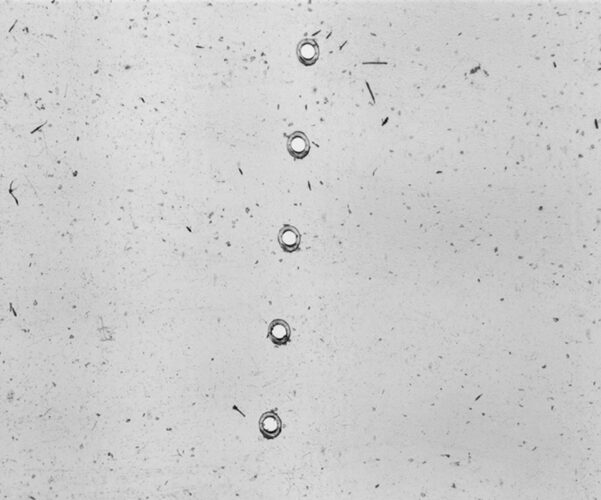

The PackMaker system is our high-performance laser system for nano and micro perforation of plastic films. Designed for the flexible packaging industry, it guarantees breathable films ideal for food preservation. VisionMaster can be integrated with PackMaker, providing real-time, in-line inspection and control to ensure every perforation meets the highest quality standards.

In the flexible packaging industry, manufacturers often face critical challenges: unnoticed defects in micro-perforations, material waste, customer complaints,

and the need to ensure consistent quality. VisionMaster addresses these issues directly, offering high-speed automatic control compatible with different plastic films, reducing waste, and boosting productivity.

Powered by advanced imaging and AI-driven algorithms, VisionMaster precisely verifies airflow through each perforation, monitors hole size and ovalization, and provides full traceability across every meter of processed material. The result is reduced waste, higher efficiency, and the confidence that every finished product meets the strictest quality requirements.

With this technological integration, SEI Laser continues to deliver advanced solutions that combine precise laser engineering with smart vision and automation, setting a new standard for quality and efficiency in flexible packaging.

- μHole Vision Master: real-time monitoring

- Intuitive operator dashboard

- Automatic teaching function

- Automatic PDF report

contacts

Do you need more information about this product?Write to us and we will contact you as soon as possible