The combination of laser and wood gives life to cutting, marking and engraving, by creating unique products.

Laser technology reduces production times, increases the range of customizations and accurately replicates design over time. Thanks to the laser, today we can realize unique customizations of a craftsmanship that is the result of man’s passion and ability.

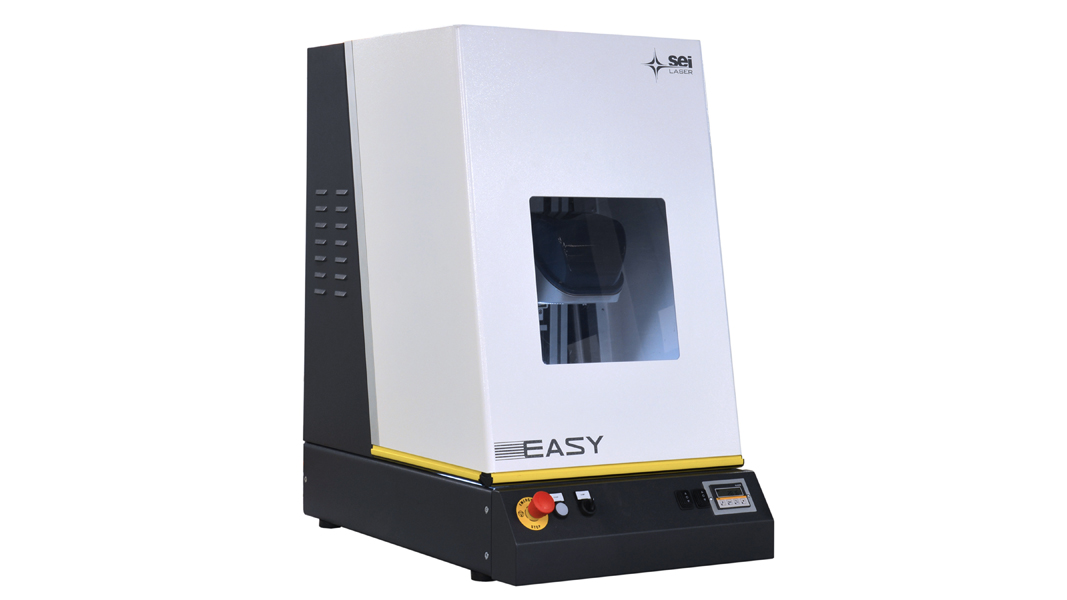

For wood market SEI Laser has developed a wide range of laser systems. Large format, medium format and small format laser cutting systems for wood, as well as laser systems for wood marking, engraving and texturing. Laser plotter systems with interpolated axes and laser systems with galvanometric scanning head: the most complete range of laser machines for the people who work in wood industry and can choose the right solution based on the type, the thickness and the format of the material to be processed.

Laser technology is an innovative, revolutionary and versatile technology which is able to satisfy any application need and it is used in numerous industrial fields in the wood industry: from interior design to furniture, from exterior design to garden furniture, from marine to arms, automotive interior, wood inlay, artistic and promotional gadgets, toys, souvenir, luxury packaging, kitchen/house accessories and architectural models.

Different types of wood can be processed: MDF and HDF, Multiplex, plywood and chipboard, natural wood, precious wood, solid wood, cork, veneer.

The key features of SEI Laser systems for wood processing are:

- Productivity: laser technology guarantees high-speed wood cutting and marking compared to traditional methods;

- Flexibility: possibility to carry out different processes (from cutting to marking and engraving of logos, writing, and images) by easy importing a file, without using milling machines or traditional cutters;

- Economic efficiency and ecosustainability: thanks to the use of laser technology, there isn’t any production waste during wood cutting as opposed to the milling machines; the power consuption is also reduced compared to traditional cutting technologies;

- Precision: laser technology allows the repeatability, the constant quality over time and the engraving of very small details that would require the patient and the wise use of engraving tools, as well as a lot of time to make them.